The studies conducted by the IPCC (Intergovernmental Panel on Climate Change) have clearly and unambiguously established that the reduction of carbon dioxide (CO2) emissions (as envisaged by the Kyoto protocol) is a mandatory path to ensure a livable world for future generations. Manufacturing companies are the first to be called upon to implement new production processes and/or use new materials that allow a reduction in the energy consumed, and therefore a reduction in the amount of CO2 emitted into the atmosphere, a sign of responsibility and respect for the environment.

*Compared to the standard 170/180°C. The estimation considers a reduction in energy costs up to 5-10% for each 10°C lowering of the curing temperature, a value influenced by different factors, for example the type of oven that is used.

A winning set of advantages, directly in the hands of the coaters:

Thanks to the different chemistries and finishes available, COOL POWDER powder coatings are excellent for both indoor and outdoor use, capable of meeting every single need of the coater: from industrial processes to applications that seek high value-added results.

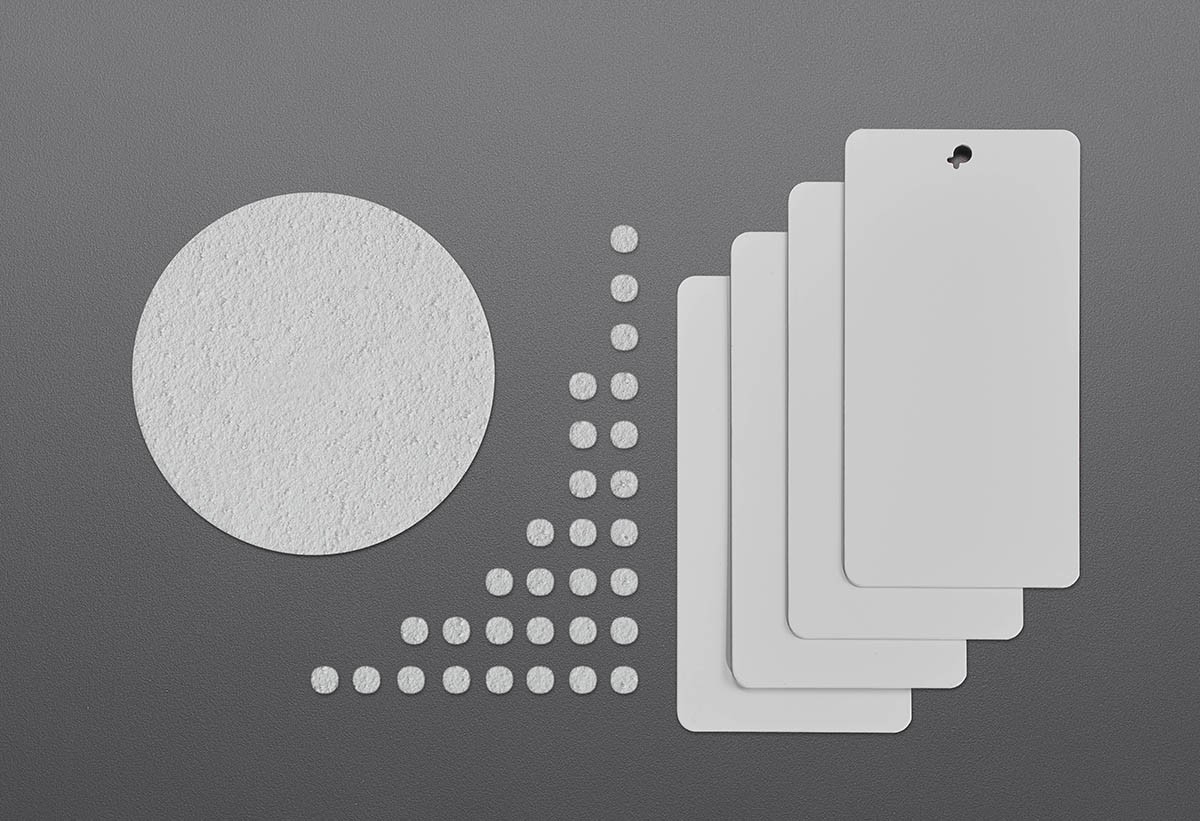

COOL POWDER powder coatings are available in these versions.

| CHEMISTRY | FINISH | BRIGHTNESS | COLOUR | CURING CYCLE |

|

Epoxy Epoxy-polyester |

Smooth |

Glossy |

Any | 140°C x 20 min |

| River texture | ||||

| Fine texture |

Matt |

| CHEMISTRY | FINISH | BRIGHTNESS | COLOUR | CURING CYCLE |

| Polyester (industrial) |

Smooth | Glossy Semi-glossy |

Any | 140°C x 20 min |

| River texture | ||||

| Fine texture |

Matt |

| CHEMISTRY | FINISH | BRIGHTNESS | COLOUR | CURING CYCLE |

| Polyester (high performance) |

Smooth | Matt | Any | 160°C x 20 min |

| Glossy Semi-glossy |

150°C x 20 min | |||

| River texture | 150°C x 20 min | |||

| Fine texture | Matt Semi-matt |

Search products

of this category

Search products